delapena tool refurbishment facility delivers first class tool refurbishment to all major honing tool manufacturers including, Gehring, Nagel, Jones & Shipman, Pemamo, Kadia, Ohio Tool Works, Animex.

We strive to deliver and exceed your honing requirements. From initial conversations right through to the delivery of your refurbished tooling. We are your trusted honing partners, providing you saving solutions in both cost and productivity.

We are with you through the entire process and gain an in-depth understanding of your companies honing requirements, including applications, abrasives selection, training requirements and more.

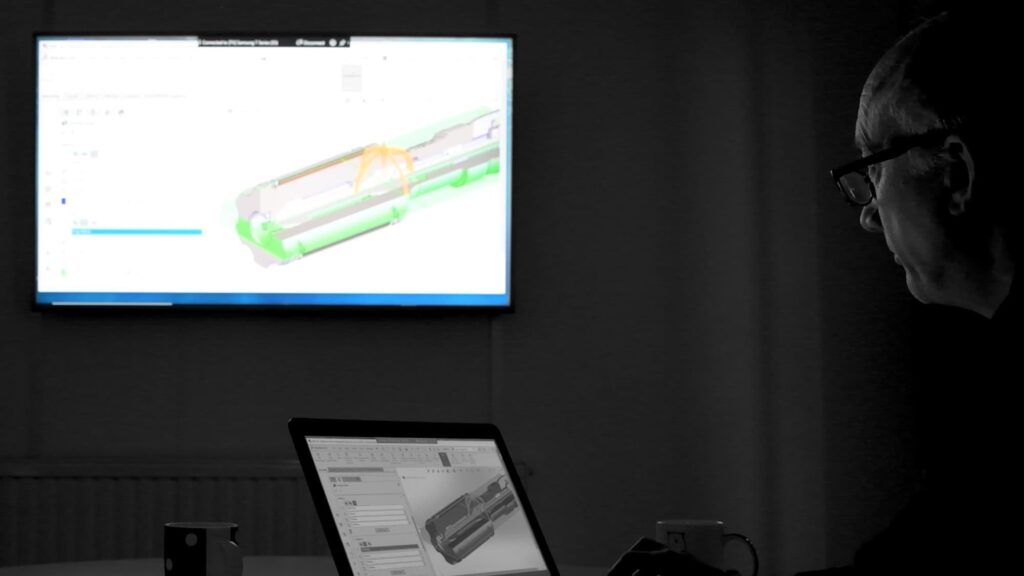

At delapena we offer our expertise and decades of honing experience to provide a honing consultancy service to the Aerospace, Automotive, Oil & Gas and Pharmaceutical Industries.

Our dedicated team focus on developing solutions and products tailor-made to our customer needs.

From innovative technology to specialised tooling, from process solutions to expert advice, we can help you improve your honing process and increase productivity.

delapena constancy service includes:

Here at delapena we know there is nothing more valuable than having staff that are fully trained in the knowledge of the honing process and equipment to create the best results.To guarantee production, which is consistent in both quality and quantity, it is imperative that you have fully trained operating personal.

To keep your components flowing at their optimal condition it is recommended you have your honing machine serviced annually. This will keep your machine running at its best and avoid problems causing unforeseen downtime and loss of production. We will send a service engineer to your premises at a mutually convenient time to give your delapena machine the service it needs.

Our service engineer checks items including the following:

With a range of electronically controlled honing machines, we are known for precise, controllable, and repeatable honing. With our subcontracting service, we not only produce the highest quality surface finish, but we can also remove the need for grinding - one efficient process replaces the expense of two, without any capital investment.

Superior subcontract honing service:

delapena offers a complete honing solution, including a suite of technically advanced machines, horizontal, vertical, heavy-duty, and special tooling, a wide range of abrasives and specialist oils.

delapena offer honing solutions with a focus on delivering the precision and consistency that our customers rely on.

We are with you through the entire process and gain an in-depth understanding of your companies honing applications and abrasives

Our applications team strive to deliver and exceed your honing requirements. From initial conversations right through to the delivery of your new tooling. We are your trusted honing partners, providing you saving solutions in both cost and productivity.

© 2024 delapena group Ltd.