Abrasive manufacturers use a variety of code numbers to identify the abrasive type, grit size, bond structure and treatments of their individual products. It is not practical to identify the various stones and so delapena use a coding system that is common for all stone sizes

Three types of conventional abrasive grit commonly used in honing.

A jagged, splinter like type of free cutting abrasive grit. Used on soft materials such as brass, bronze, aluminium and cast iron, and very hard materials such as carbon, ceramic, and hardened steels.

A regular, chunky shaped grit used for deburring all materials and stock removal in most soft steels up to HRC 50.

A special purified form of aluminium oxide having a cool cutting action. Used on wear resistant materials such as hard chrome and heat-treated steels above HRC 50.

Stones suffixed "s" are sulphur treated. An extreme pressure lubricant that helps to reduce heat, reduces clogging and loading of the stone surface and reduces pick up in softer materials.

A range of polishing stones that will produce a high degree of surface finish on most materials.

A cork stick impregnated with fine abrasive grit used for polishing especially stainless steels.

A cork sticks are predominantly used in plateau honing of cylinder bores.

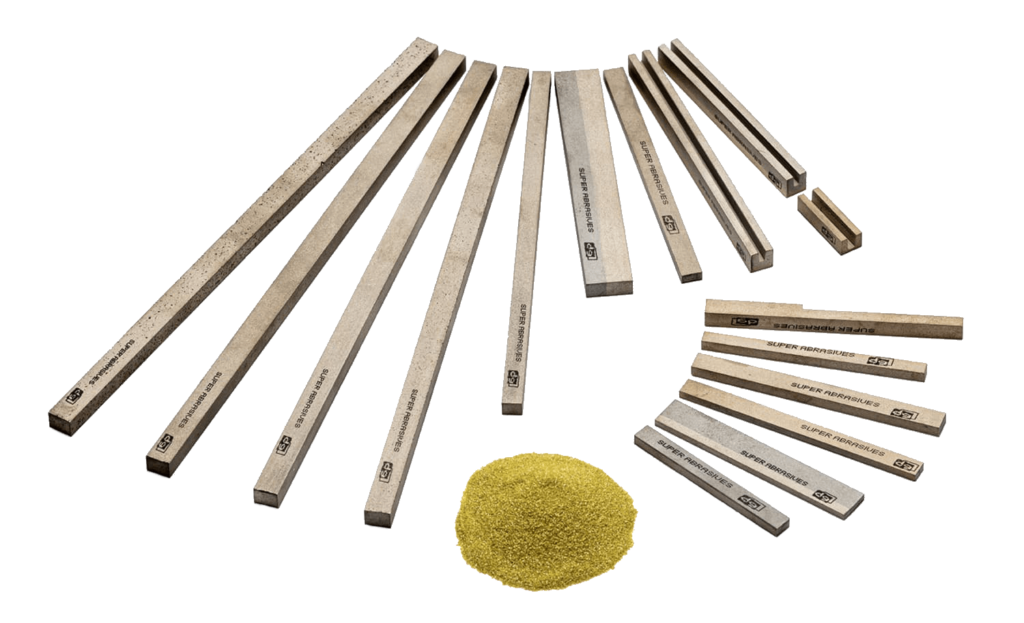

Diamond honing stones in metallic and resinoid bond have been used successfully for many years. These hones are subjected to higher working pressures and surface speeds than conventional abrasives.

The main field of application has been honing tungsten carbide and ceramics where, because of the material hardness, conventional vitrified abrasives are unsuccessful. In certain other areas the use of diamond hones can result in a reduction in honing costs. Examples of applications in these areas are:

A hard bond used for tungsten carbide with cobalt content above 25%. Also used for cast iron, glass, ceramic etc.

A medium bond used for tungsten carbide with cobalt content 11% - 25% and used on most heat-treated steels above HRC63.

A soft bond used for tungsten carbide with a cobalt content of >11% and used for other extremely hard materials.

There are two types of bonding materials to determine the hardness of the CBN hone. The harder stone for interrupted bores, short bores or when the pre hone finish is poor.

A soft bond used for tough hardened steels including titanium up to HRC63. Also suited to sintered materials such as Alnico and special alloys like Inconel.

Generally used at higher speeds and lower pressure than diamonds or standard abrasives. Always use the lowest pressure that will give a good cutting action. Increasing the pressure beyond this point will result in increased stone wear with very little increase in stock removal.

A medium bond used for components having interrupted bores (cross holes, annular grooves, etc) or when the surface finish prior to honing is poor.

Because the bonding material is harder, this material can be used at higher pressures than the resinoid stone and can therefore be used if satisfactory results cannot be achieved with the "BR" bond.

We manufacture a complete range of Rottler type replacement stones available in CBN and Diamond to meet all your honing needs. Our honing stones are available in standard sizes to meet OEM (Original Equipment Manufacturers) specifications.

Available in 76mm, 89mm and 102mm long with abrasive grit sizes from 80 grit to 1200 grit as standard. We also offer bespoke options available on request.

The honing stones are manufactured and evaluated with the latest equipment to ensure high quality and meeting OEM (Original Equipment Manufacturers) specifications.

Rottler compatible (generic) honing stones manufactured to fit your Rottler type machines and tooling.

delapena sintered products have developed and supply a full range of Sunnen equivalent 'K' Series super abrasive stone assemblies fully compatible with the OEM mandrels.

We can supply a complete range of equivalent ‘NM and ’DM’ series super abrasives in all grit sizes and hardness specifications.

We can also supply replacement ‘P28’ and ‘H70’ super abrasive stone sets fully computable with OEM equipment.

Contact our sales team for more information sales@delapena.co.uk

© 2025 delapena group Ltd.