A major breakthrough in the maintenance of aircraft, allowing onsite honing of critical components, enabling aircraft back into service quicker.

delapena has a reputation for providing an extensive range of honing machines, tooling, and ancillary equipment. That reputation has now been enhanced following the development of a series of Alignment Hone tools targeted at aircraft maintenance. These simple, yet innovative hone tools allow major structural elements of aircraft to be re-machined In-Situ, eliminating the need for expensive dismantling and reassembly, resulting in significant savings in time and cost.

Working in conjunction with leading airline maintenance companies, delapena has created a tool that will produce precision honed surfaces and maintain the centreline of two independently honed bores.

“The ability to hone bores on assemblies such as landing gear, without having to remove them from the aircraft is a significant breakthrough in reducing aircraft downtime and reducing maintenance costs,” Paul Lane, Global Technical support engineer.

Alignment Hones are manufactured to customers’ specific requirements and applications include the honing of side stays, gear ribs, retract jacks and engine pylons. Each kit is supplied with a drive shaft and truing sleeve to ensure that everything that is needed to complete the process is ‘in the box'.

Alignment hones are a simple but revolutionary way to hone and service aircraft without the need for expensive and time-consuming dismantling. Developed in conjunction with industry leaders, these tools provide precision honed surfaces whilst maintaining the centreline of the two bores without the need to remove the components from the aircraft.

Typical applications already using this range.

A320 Side Stay Gear Rib

A330/340 Side Stay Gear Rib Retract Jack

A350 Pylon

A380 Side Stay Gear Rib

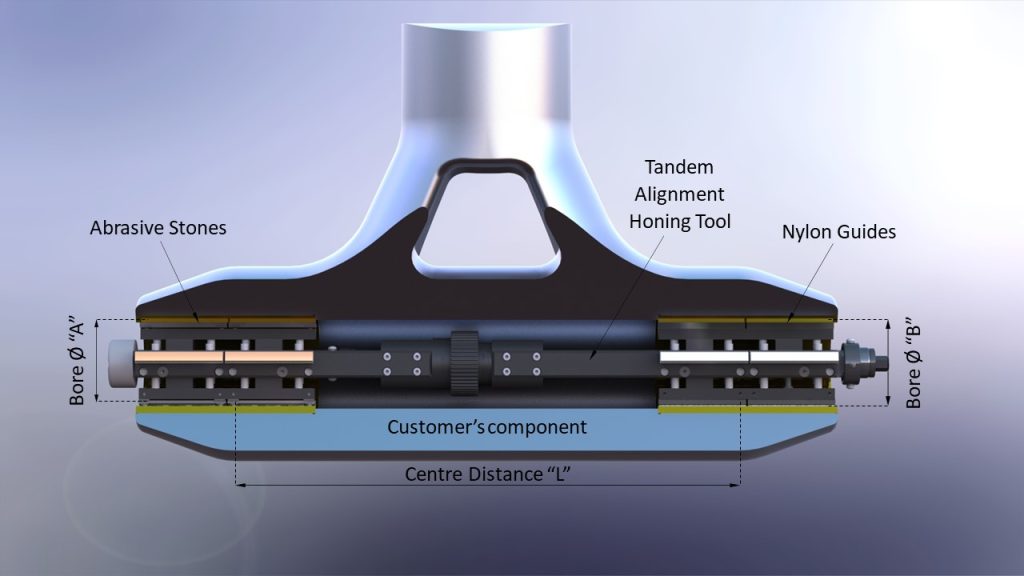

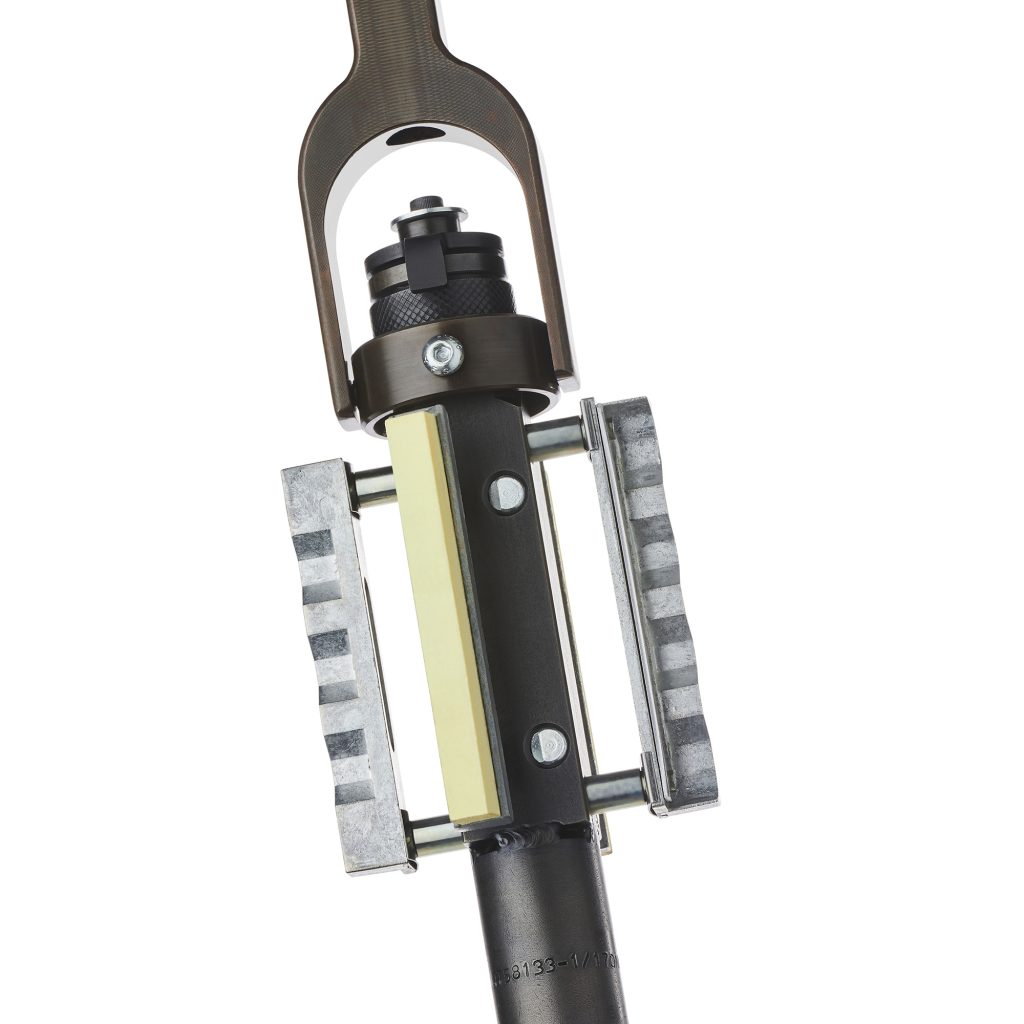

The tool body is made such that its length matches the centre distance of the two ‘in-line’ bores. One end of the tool is fitted with abrasive stones and the other with nylon guides.

When the tool is inserted into the bores the nylon guides are expanded to pilot the tool in one bore while the honing stones are expanded to increase the diameter of the bore to be honed. When the first bore has been honed to the correct size the tool is removed and inserted from the opposite end so that the nylon guides are piloted in the honed bore while the stones increase the diameter of the second bore. If access is restricted and the tool cannot be inserted from each end of the tandem bore then the position of the honing stones and nylon guides are reversed in the tool after the first bore has been honed.

delapena honing tools are manufactured to exact customer requirements and supplied with Driveshafts and optional Truing Sleeve.

These tools use all delapena standard consumable parts.

Standard vertical honing head range of tools are used.

Midget - 1201/1202 25.4-38.1 mm/ 1.00-1.50 ins

Minor - 1203/1204 38.1-55.8 mm/ 1.50-2.20 ins.

Junior - 1205/1206 50.8-68.3 mm/ 2.00-2.68 ins

Standard - 1207/1209 65-752 mm/ 2.56-29.61 ins

Major - 1209/1210 65-752 mm/ 2.56-29.61 ins

| Tandem Line Hone | Tandem Truing Sleeve | Component |

|---|---|---|

| MT58133/170 | MT19002/170 | Gear Rib/MLG |

| MT58133/191/1 | MT19003/191/1 | Side Stay |

| MT58133/347/1 | MT19033/347/1 | Side Stay |

| MT58133/244 | MT58254 | Gear Rib/MLG |

| 1207 Standard Head | MT19065 | Retract Jack |

| MT58133/244 | MT58254 | Gear Rib/MLG |

| MT58133/355 | MT19033/355 | Side Stay |

| 1207 standard Head | MT19064 | Retract Jack |

| MT79007/611 | MT19048/611 | Pylon |

| MT58133/264 | MT19039 | Gear Rib/MLG |

| MT58133/382 | MT19048 | Side Stay |

| MT58133/150 | MT19003/150 | Retract Jack |

| MT79000 | Alignment Hone - Midget & Minor head at 130mm centres |

|---|---|

| MT79000 | Alignment Hone - Midget & Minor head at 130mm centres |

| MT79001 | Alignment Hone - Minor & double Minor head at 723.9mm centres |

| MT79002 | Alignment Hone - Midget heads at 630.46mm centres |

| MT79003 | Alignment Hone - Minor heads with adjustable centres at 185 & 220mm |

| MT79004 | Alignment Hone - Midget & Minor head [Ø1.25" & 1.9375" bores] |

| MT79005 | Alignment Hone - Standard heads at 197mm centres [Driven from one end only] |

| MT79006 | Alignment Hone - Standard & Junior head at 268mm centres |

| MT79007 | Alignment Hone - Major, Major Head at 611mm centres |

| MT79008 | Alignment Hone - Minor, Minor Head |

| MT79009 | Alignment Hone - Double Minor head |

| MT79010 | Alignment Hone - Double Reduced Midget head Ø22.8 |

| MT58130-XX | Midget Alignment Hone |

| MT58131-XX | Minor Alignment Hone |

| MT58132-XX | Junior Alignment Hone |

| MT58133-XX | Standard Alignment Hone |

© 2025 delapena group Ltd.